Prior to edging, the spray system casts a fine layer of separating agent over the top and bottom of the workpiece edges.

Standard interchangeable glue pots with stop function for rapid change of colour or technology (EVA/PUR)

Pre-milling system with interchangeable diamond cutter tips ensures maximum tool life (manual height adjustment)

Feed speed

LED Touchscreen

Heated

You can intuitively set up your machine via the 10” touchscreen on the front and view all key information at a glance.

The stable design of the double motor trim saw unit with linear guides enables precise milling of the front and/or rear workpiece

The edgebander requires only 10 minutes to reach operating temperature. Tool-free quick change system is suitable for EVA and PUR hot melt adhesive granulates.

Plane impacts or milling traces are smoothed down thanks to even cutting by the radius scraper.

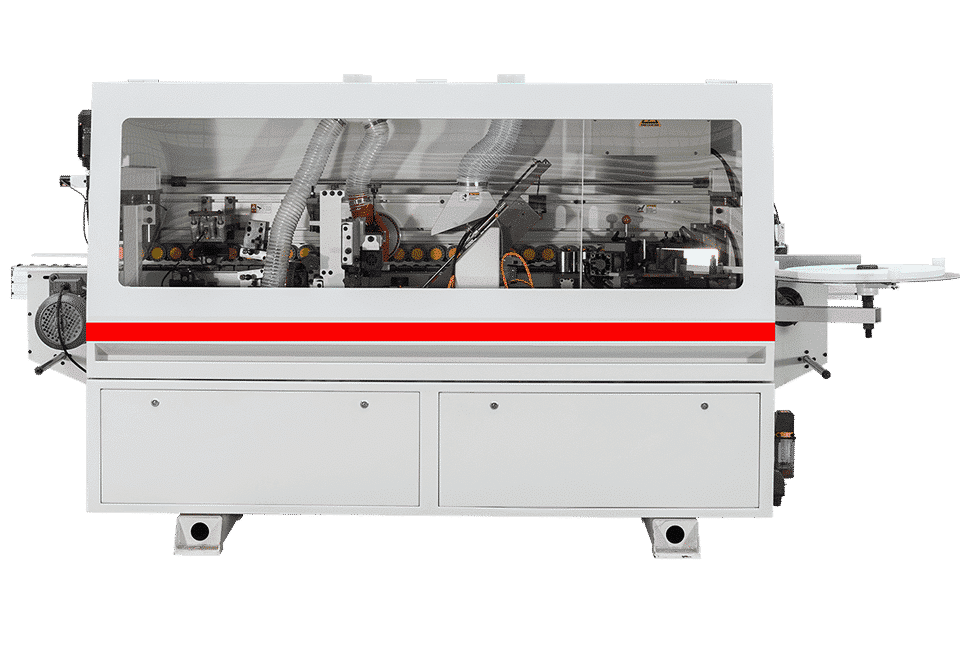

Made for the highest demands

Exterior

Modern, optimized edge processing aggregates and a flexible machine body guarantee absolute stability and reliability even at maximum processing speeds.

Cleaning agent spraying unit

This spray system applies the cleaning agent to the top and bottom of the workpiece. Applying the cleaning agent followed by the cleaning station removes any sprays, adhesives and impurities.

Feeder Plate

The feed plate uses a graduated scale for precise and quick adjustment of the conveyor size of the processed plates.

In our configuration form you can put together your desired configuration of the X 400 according to your requirements and send it directly to us.

| Packing | Net/Gross | Dimensions of box |

| Edgebanding Machinery box | 2050/2250 kg | 3920*770*2600 mm |

Explore More Fun from Speedx Machinery.